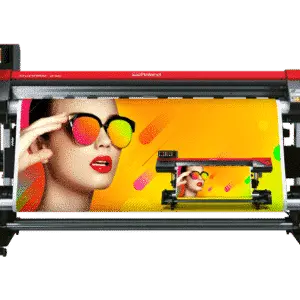

Markedly, TrueVis VG3 technology is an all-in-one solution, transforming thousands of businesses worldwide. Indeed, VG3 combined printers are entering a new stage in digital evolution. With them, Roland delivers a new and closer opportunity to confidently expand your business.

General information

These combined printers provide precise contour cutting for incredible printing performance. VG3 printheads represent the new Roland FlexFire class. The redesigned chassis, high-quality components and a variety of media-handling improvements make the TrueVis VG3 series perfect for unattended short and long runs, outline print & cut jobs, and more.

New features of the TrueVis VG3 series

- A 7-inch LCD touch control panel allows you to monitor all print process parameters. It also offers automatic calibration and other automated intuitive tools.

- Media take-up unit – redesigned with adjustable end cap. Flexible use of spools of different sizes – included with each VG3 large format printer.

- Automatic media gap adjustment function: Media gap and media feed compensation are adjusted at the touch of a button.

- Nozzle Mask Function: If a printhead nozzle does not work, a specific nozzle band can be turned off, so printing continues immediately without interruption.

- Custom cutting: Create labels and decals with even greater precision using the Crop Mark by Row feature of the VersaWorks 6 software.

- Smart media clamps: Clamps with built-in channels make the operation more efficient when printing. They do not interfere with media sheet cutting and there is no need to remove them.

- Perforated cut option for tearing off the printed media: Easy to tear perforation between prints, quick separation of the finished printed media.

- New media holder: One-touch lever locks the roller in place. Other easy-to-load features include an integrated fan – which keeps the media stable during prior-to-print preparation.

- Automated pinch rollers: The renewed inner pinch rollers get lifted during cutting, while the outer pinch rollers remain pressing. In this way, they ensure precision during printing and excellent contour cutting results.

TrueVis TR2 Inks

Developed for SG2 / SG3, VG2 / VG3 series of print & cut machines, Roland TrueVIS TR2 inks achieve exceptional colour. At the same time, they meet high environmental standards. Furthermore, you get precise special colours in company branding or logo printing projects. The result is incredibly bold, vivid prints with the tremendous colour power of the TR2 inks in VG2 / VG3 printers.

- Specially formulated, quick-drying, ecosolvent inks.

- Striking, vibrant colours – typical of Roland printers.

- New GREENGUARD Gold TrueVIS certified system – packed in convenient ink bags, 500 ml. Upon installing in their slots, they slide into a discreet, compartment in front of the printer housing. This provides easy access and cleaner operation with much less waste.

Many of the new features are also in the new 4-colour TrueVis SG3 printers, as well as here.

Download the VG3 brochure for specifications and more printer details.

Reviews

There are no reviews yet.