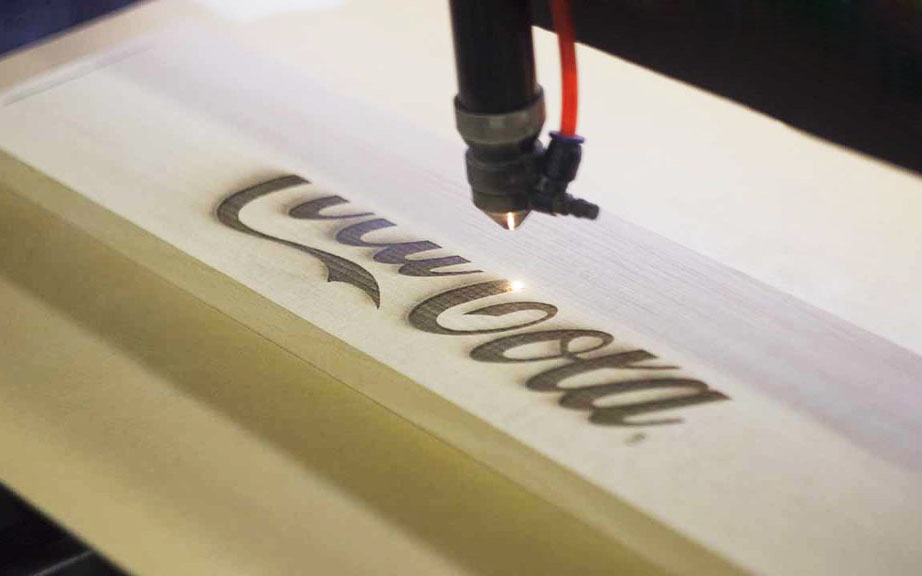

Above all, this Universal Laser Systems VLS4.60 machine is fully equipped. Used as a showroom demo unit, it is virtually new. In the first place, it is suitable for various applications. Such as laser cutting, precise marking, fine engraving Thus, it is a real profit source. Especially, if combined with a UV printer, even desktop size.

Description:

Universal VLS4.60 Laser Cutter / Engraver

Condition: Perfect, like new. Demonstration unit.

50 Watts / New tube installed in June, 2019

ULS Laser Manufacturer’s data:

Laser Material Processing Area (W x H) – 610 x 457 mm

Maximum Part Size (W x H x D) 737 x 584 x 229 mm

Motorized Z Axis Lifting Capacity 18 kg

Overall Machine Dimensions (W x H x D) 914 x 965 x 914 mm

Weight 120 kg

Power Requirements 220V-240V/5A

Exhaust Requirements: 102 mm diameter, 425 m3/hr at 1.5 kPa

Configuration:

Laser cartridge – 50 W.

Standard Focus Lenses 50 mm.

Downdraft Cutting Table.

HPDFO™ (High Power Density Focusing Optics) /optional/.

Rotary Axis Unit /Max material diameter: 203 mm/.

Optics Protection – Coaxial Air Assist.

Original ULS software, Printer Driver. Direct Import Feature for uploading graphic designs.

Universal Control Panel provides an Intelligent Materials Database. Equally, it calculates optimized settings for laser processing on variety of materials.

Laser Platform Interface Panel Five button keypad.

Cabinet Style Free-Standing.

Here is some additional information:

Above all, it is easy to use: Allows laser cutting, engraving, and marking to be executed in few steps.

Second, time saving features maximize productivity: Direct Import, Materials Database, Duplicate, Estimate, Storage.

Then, it allows manual control: Enables to enter individual laser settings for unique materials and applications. In this way it provides unlimited processing flexibility.

Further, enables the Camera Registration option. So, it automatically compensates material misalignment or stretching. So, ensures accurate processing.

Also, a continuously growing database of applicable materials helps optimal results.

At the end, it gives you possibility to control laser processing parameters when needed.

This VLS4.60 laser platform supports a 9.3µ CO2 50W laser source.

Digital Motors:

Additionally, ULS use high quality digital motors. These allow to avoid the expensive and complicated optical encoders. As a result, they ensure high reliability at a reduced cost.

ULS Laser Energy Management Engine:

Shortly, consistent energy density at any processing speed. Thanks to it, uniform marks and constant depth are guaranteed. And it applies for cutting, marking and engraving.

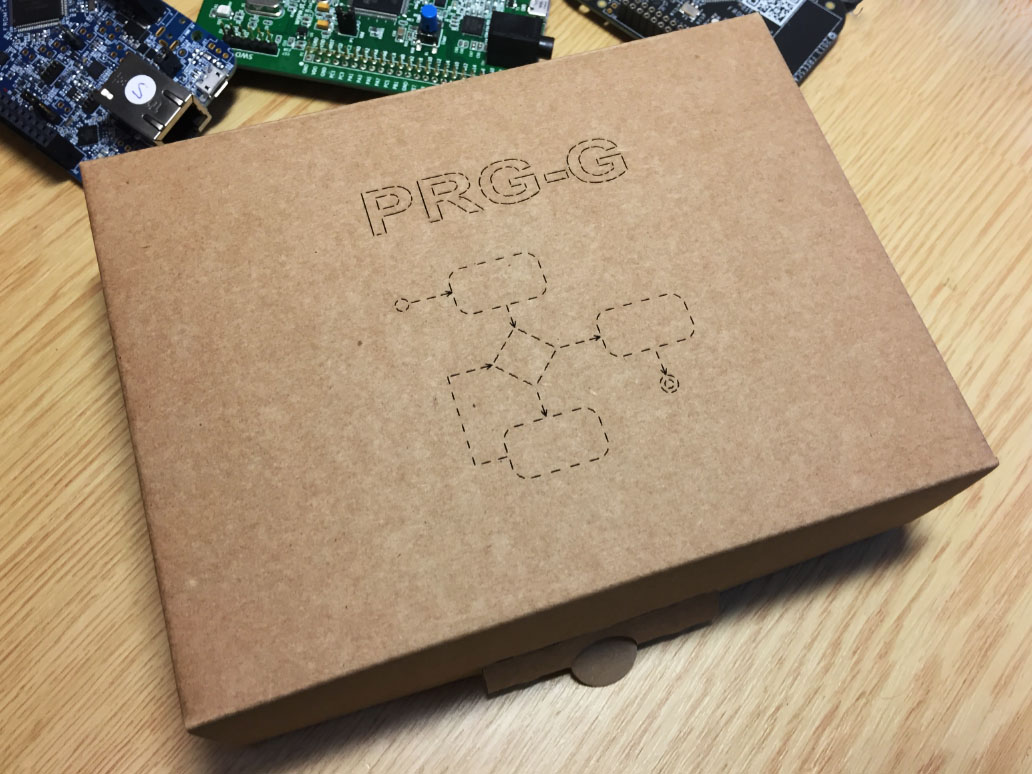

Examples – different laser materials jobs

Reviews

There are no reviews yet.