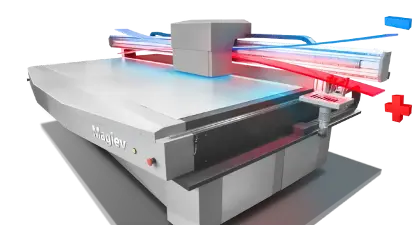

Besides its capability to print large and extra large printing sizes and volumes, IQDEMY Maglev UV printer is an intricate and precise technology solution.

Stone table

The Maglev UV printer has a powerful linear motor. Its maximum traction force rises up to 21,500 joules. Thus, it is able to accelerate the carriage speed up to 500m/min in just 0.1 seconds by the electromagnetic force. In this way, the printing speed exceeds any standard mechanic solutions. Since there are no rubbing and stepping components, it eliminates the negative vibrations and «noise». In addition, this increases the print quality and overall stability and durability of the system. Magnetic Levitation Technology is a step forward in ink-jet multi-pass printing like never before.

Advanced grey-scale (Ricoh Gen5 only)

Particularly, an improved waveform monitoring system helps Iqdemy Maglev to print eight dots of different sizes at once. Thus the smoothness of the color transition significantly increases. So it allows making gradients (e.g. human skin and sky tone gradations) look perfect. And all these without speed loss. Even by optimizing further the ink consumption.

Two-colors in one print head (Ricoh Gen5 only)

In fact, the printer can perform CMYK with only two print heads in a true 300 dpi. Besides this, the advanced control electronics allow using of up to 8 print heads. Then the machine delivers maximum print speed in a wide color range.

The minimum droplet size is about 3.5 pl (+/- 10%) (Ricoh Gen5 only)

The combination of Variable Dot® technology and Technology of Invisible Dots® by DPS Innovations enables to half the minimum droplet size to get the sharpest image.

White ink recirculation

The continuous circulation system stands for no ‘white’ print head clogging.

8 channels in every machine

Maglev provides 8 color printing. With the addition of CMYK+W and with adding print heads to have +LM+LC+V you can have the most versatile machine of its class.

Control electronics by DPS Innovations

All control systems and side components come from DPS innovations. They are specially developed and made for IQDEMY Maglev. As a result, you get the maximum of the print head capabilities at no banding or other print defects..

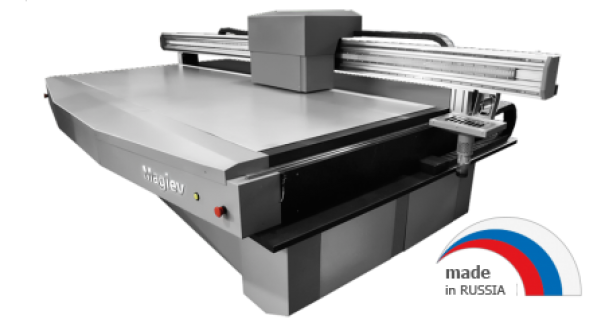

IQDEMY Maglev construction details

Solid frame

The fully metal-welded frame can handle even heaviest media. The machine has wheels and legs in order to be easily moved and for extra stability during work.

4 vacuum zones

The Honeycomb desktop is divided into 6 zones of vacuum. So, they can operate independently thus reducing the power consumption. The panel has a composite coating, further perforated for continuous vacuum supply. It is fixed by magnets and therefore it’s replacement is easy.

I-beam and guide-frames

The carriage motion system includes specialized guides, mounted on an aluminum I-beam. Step- motor with leadscrew provides automatic adjustment of the carriage height making your work a lot easier.

10 tanks for ink supplying and ink level sensors

The ink delivery system consists of 10 tanks (8 for colors and 2 for air). Each container includes a mechanical sensor measuring the level of a residue, pre-filter, cleaning system of electronic valves, and diaphragm pump for pumping ink into the system, fine filter and ink supplying path. Vacuum systems for CMYK and White color are independent. This is the most reliable scheme in industrial ink-jet printing for now.

Olav Karljes –

A really good quality machine. Open architecture, log time warranty and good support.